Description

CONTROLS Stress path triaxial and uniaxial automatic test system is designed to test various materials, from soft sandstone to high strength marbles.

The test system comprehends:

ADVANTEST ROCK, servo-hydraulic control console for axial load application in conformity with the relevant Standards. Includes a dedicated software for triaxial testing which also controls the SERCOMP ROCK and automatically determines the sample failure envelope. The ADVANTEST ROCK performs loading-unloading ramps and can also be used for load/stress/displacement/strain controlled testing on concrete, fiber reinforced concrete, shotcrete, etc. (with the suitable options and accessories)

SERCOMP ROCK. Servo-hydraulic control console for confining pressure control into the Hoek cell (triaxial test only). It runs as a remotely controlled unit, fully operated by the Advantest Rock software. Includes 4 additional channels for strain / displacement transducers.

ADVANCED SOFTWARE: ADVANTEST ROCK and SERCOMP ROCK are linked to a single PC for data acquisition and results elaboration.The overall test information and readings are always available on the PC screen:

Axial load and sample strength

Hoek cell confining pressure

Sample deformation measured by strain gauges and external displacement transducers

Plus any additional load/strain/displacement readings from external transducers that may be useful for research purposes.

HIGH STIFFNESS COMPRESSION FRAME to be selected from the wide CONTROLS product range, conforming to the size of the sample and the expected strength. Due to the typical high strength and fragility of rocks we recommend high capacity test frame (4000kN or 5000kN capacity).

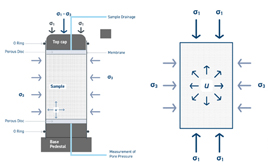

HOEK CELL: various models for different sample size are available: from EX type with dia. 21.46 mm up to HQ type for core with dia. 63.5 mm.

Triaxial test is carried out automatically with multiple failure stages: from a single specimen it is possible to plot the entire failure envelope,

Test procedure

Axial and horizontal stresses are increased hysotropically up to a defined level

Cell pressure is maintained constant and axial stress is increased

When the sample approximates maximum strength, the cell pressure is automatically increased up to a defined level

Cell pressure is again maintained constant and axial stress is increased

When the sample again approximates maximum strength, the cell pressure is further increased

The above procedure is automatically repeated several times

Maximum peak strength is reached and, in case of displacement control, the test is continued (softening phase)

Cell pressure is reduced in steps and, for each step, the residual strength is measured

All the maximum peak loads are plotted against corresponding values of cell pressure building the complete failure path.

For a typical configuration of an Automatic triaxial test system ask the cooperation of our specialists.

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk  Whatsapp Enquiry: +85261990717

Whatsapp Enquiry: +85261990717